The flour milling industry is one of the vital pillars of the food supply chain, ensuring the quality, efficiency, and safety of the final product through the use of advanced technologies. Modern flour mills utilize a combination of mechanical, electronic, and industrial automation equipment to convert wheat into flour with high precision and speed.

Wheat Receiving and Preliminary Cleaning Unit

🔹 Wheat receiving systems include chain conveyors, belt conveyors, and bucket elevators that transfer wheat from trucks or silos to the processing lines.

🔹 Primary cleaning machines, such as pre-cleaners, magnetic separators, vibrating screens, and air separators, are responsible for removing physical impurities (stones, soil, metals, straw, etc.).

- Wheat Cleaning and Preparation Section

🔹 Precise cleaning is carried out using machines such as gravity separators, sizers, and color sorters.

🔹 Washing and conditioning systems, including washers and dampeners, adjust the moisture content of the wheat to optimize milling performance.

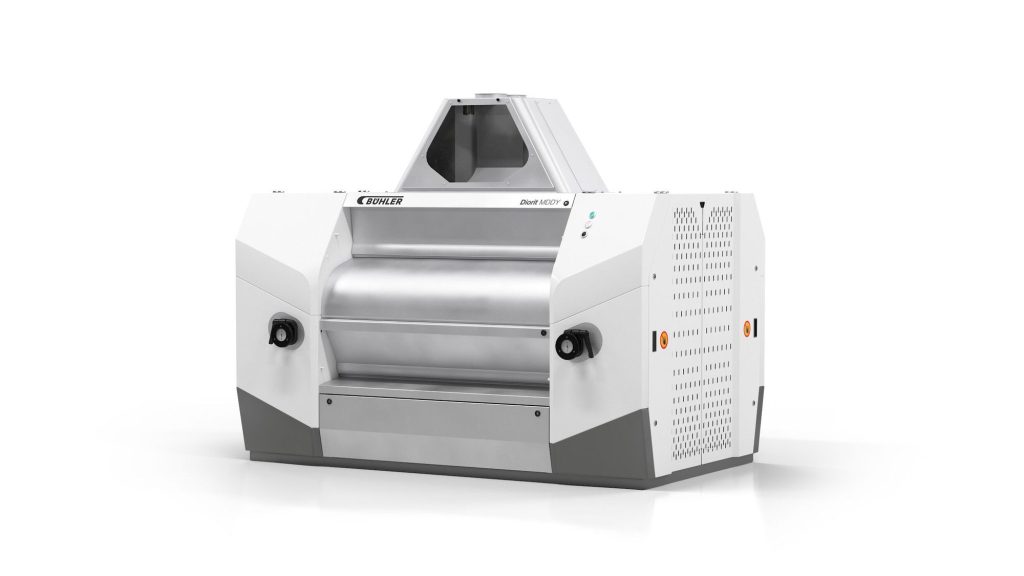

Milling and Grinding

🔹 Roller mills are the heart of a flour mill. These mills gradually crush the wheat using hardened steel rollers, turning it into flour.

🔹 Mills are designed in several stages (Breaking, Reduction, Semolina) to ensure precise separation of the bran, endosperm, and germ.

- Sifting and separation systems

🔹 Plansifter sieves, with multiple layers and various screens, classify flour particles according to their size.

🔹 Air classifiers are used to separate lighter particles, such as bran, from the flour.

Conveying and storage systems

🔹 Pneumatic and mechanical conveyors are responsible for transporting materials between units.

🔹 Flour storage silos, designed to be moisture-resistant and equipped with ventilation systems, store the flour until packaging.

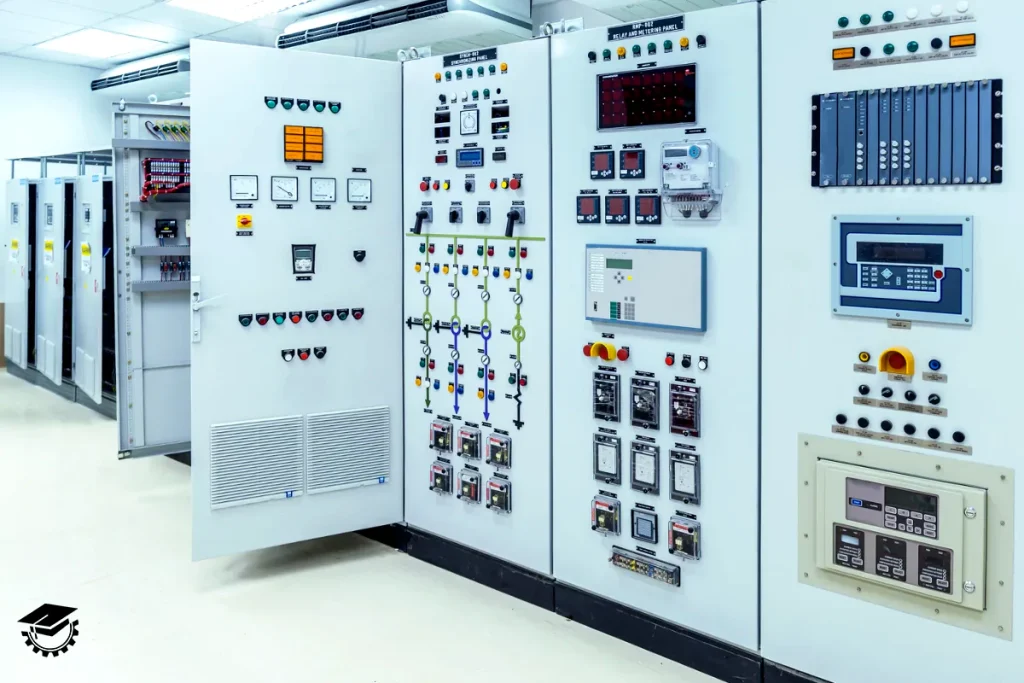

- Quality Control and Automation Unit

🔹 PLC and SCADA control systems monitor and adjust the production process in real-time.

🔹 Quality control laboratories, equipped with instruments for analyzing moisture, gluten, ash, and color, ensure the quality of the flour.

- Packaging and Weighing

🔹 Automatic packaging machines, with precise weighing, heat sealing, and information printing capabilities, package the flour into various bags.

🔹 Digital weighing systems ensure high accuracy in product delivery.

Modern Technologies in the Flour Milling Industry

✅ Utilizing industrial automation and artificial intelligence to optimize energy consumption and reduce waste

✅ Employing online monitoring systems to control temperature, humidity, and pressure in production lines

✅ Sustainable and green technologies:

• Designing production lines for optimal water and energy usage

• Heat recovery and reduction of carbon dioxide emissions in milling processes