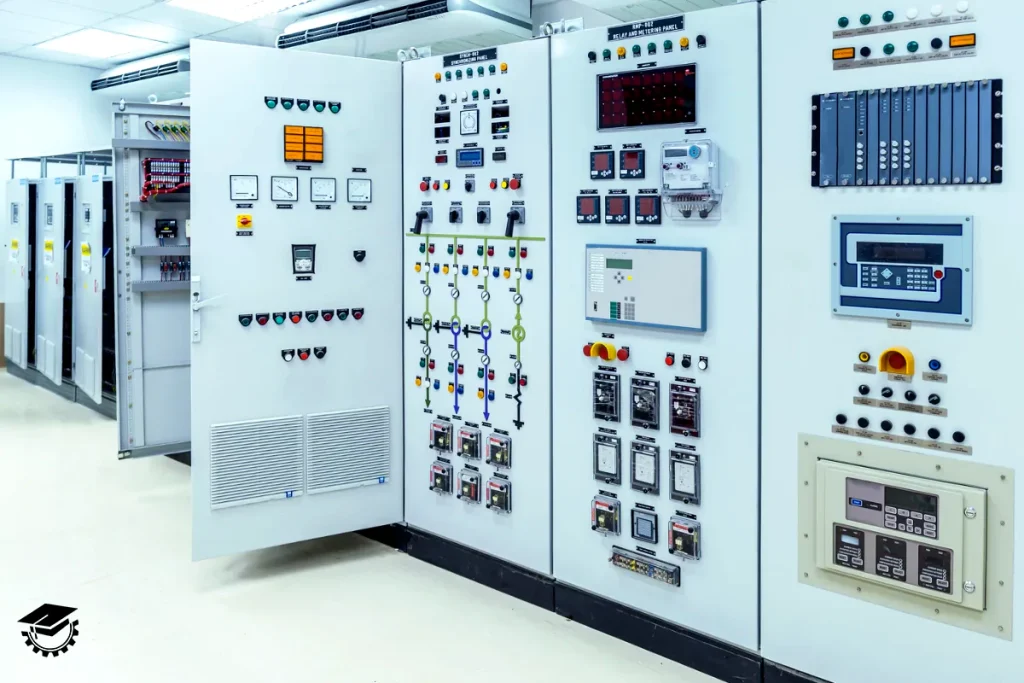

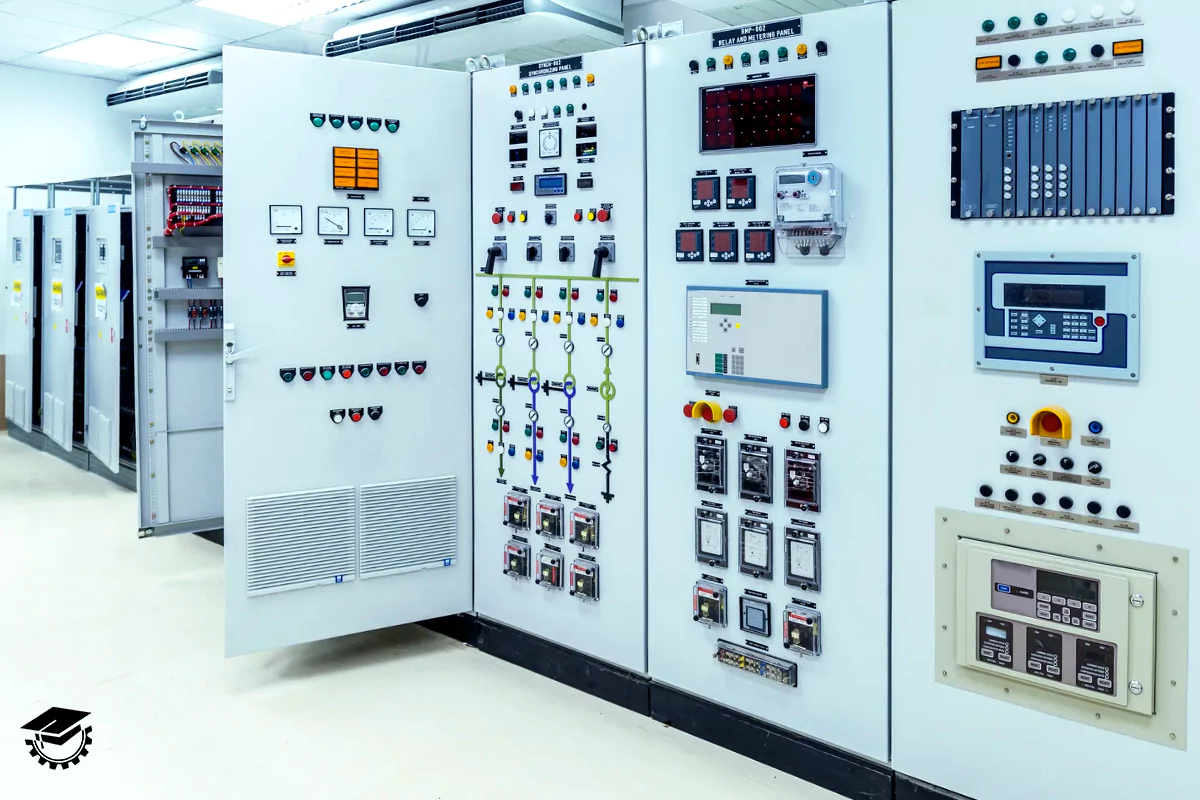

An industrial electrical panel is one of the vital components in power control and distribution systems in factories, workshops, and large facilities. These panels are responsible for protection, control, and power distribution, playing a key role in the safety and efficiency of electrical systems.

🧩 Main Components of an Industrial Electrical Panel

Ventilation System or Fan: To prevent overheating and maintain equipment performance.

Durable Metal Enclosure: Usually made of steel sheets with electrostatic coating to resist corrosion and impact.

Switches and Circuit Breakers: Including miniature breakers, automatic switches, and fuses for protection against overload and short circuits.

Copper or Aluminum Busbars: For transmitting current between components with minimal voltage drop.

Contactors and Relays: For controlling motors and industrial equipment.

PLC Panel and Control Devices: Found in advanced panels for industrial automation.

🛠️ Types of Industrial Electrical Panels

Capacitor Bank Panel: Improves power factor and reduces energy consumption.

Distribution Panel: Distributes electricity among different sections of the factory.

Control Panel: Manages industrial processes and machinery.

Power Panel: Handles high currents for large motors.

Automation Panel: Executes control programs using PLC and HMI.

In recent years, SPSKZ has carried out numerous projects in the flour, animal feed, and grain silo industries. Some of these projects include:

Installation of capacitor bank panels and motor protection systems.

Design and installation of distribution and control panels in flour mills.

Implementation of power and ventilation panels in grain silos.

Assembly of automation panels with PLC in animal feed factories.