In line with enhancing product quality, improving efficiency, and aligning with modern milling industry standards, a production line upgrading project has been launched, focusing on the installation of advanced Purifier machines and the establishment of a new wholemeal flour production line. This project has been carried out with specialized consultancy, equipment supply, and installation by SPSKZ, in technical collaboration with Ocrim Italy, one of the world’s most renowned manufacturers of milling machinery.

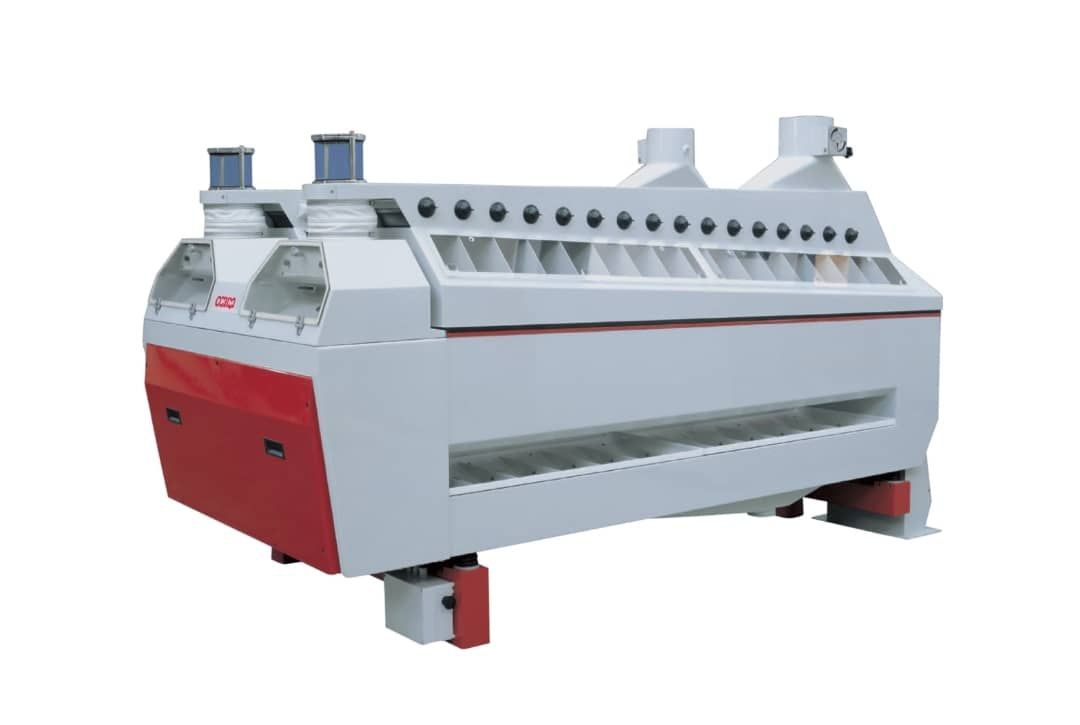

In the upgrade phase, advanced Purifier sieving machines are replacing older equipment to improve particle separation accuracy, enhance flour quality, and reduce waste. This enhancement optimizes the production process and increases the efficiency of existing production lines..

Simultaneously, the establishment of a new whole flour production line utilizing an advanced stone mill is underway. This line is designed with a focus on preserving the nutritional value of wheat, producing healthy and natural flour, and meeting the demands of health-conscious markets. The selected stone mill, from Ocrim, with modern technology, stable performance, and high-quality construction, ensures the production of whole flour with authentic texture and flavor.

Key Features of the Project:

- Installation of high-precision Purifier machines with optimized energy consumption

- Establishment of an independent whole flour production line with an advanced stone mill

- Enhancement of automation and production process control

- Expansion of product variety to meet both domestic and export market demands

This project represents a significant step in modernizing the factory’s production infrastructure and strengthening its position as a producer of specialized, high-quality flour at both regional and international levels.