In line with improving milling process performance, enhancing the quality of the final product, and aligning with modern flour industry standards, the project to upgrade the production line, focusing on the installation of advanced Plansifter machines, has been initiated. This project has been executed with specialized consultancy, equipment supply, and installation by SPSKZ, in technical collaboration with Ocrim Italy, one of the world’s most reputable milling machinery manufacturers.

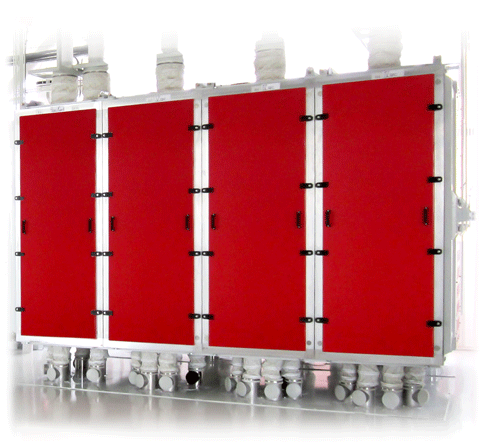

Plansifters, as one of the key components in the flour particle separation and grading process, play a vital role in ensuring product quality and consistency. In this project, outdated equipment has been replaced with new, advanced Plansifter models, featuring high precision, optimized energy consumption, hygienic design, and compatibility with automation systems.

Key Highlights of the Project:

Improved separation process and increased production efficiency

Reduced maintenance costs and extended equipment lifespan

Specialized consulting in selecting the appropriate Plansifter models based on capacity and product type

Equipment supplied from the reputable brand Ocrim, meeting European standards

Installation and commissioning by the SPSKZ technical team, ensuring safety and efficiency